Polycarbonate 3d Printing Material Properties

For most but not all materials we have dedicated data sheets published by their manufactuers with additional data let us know which you need and we ll email them over to you.

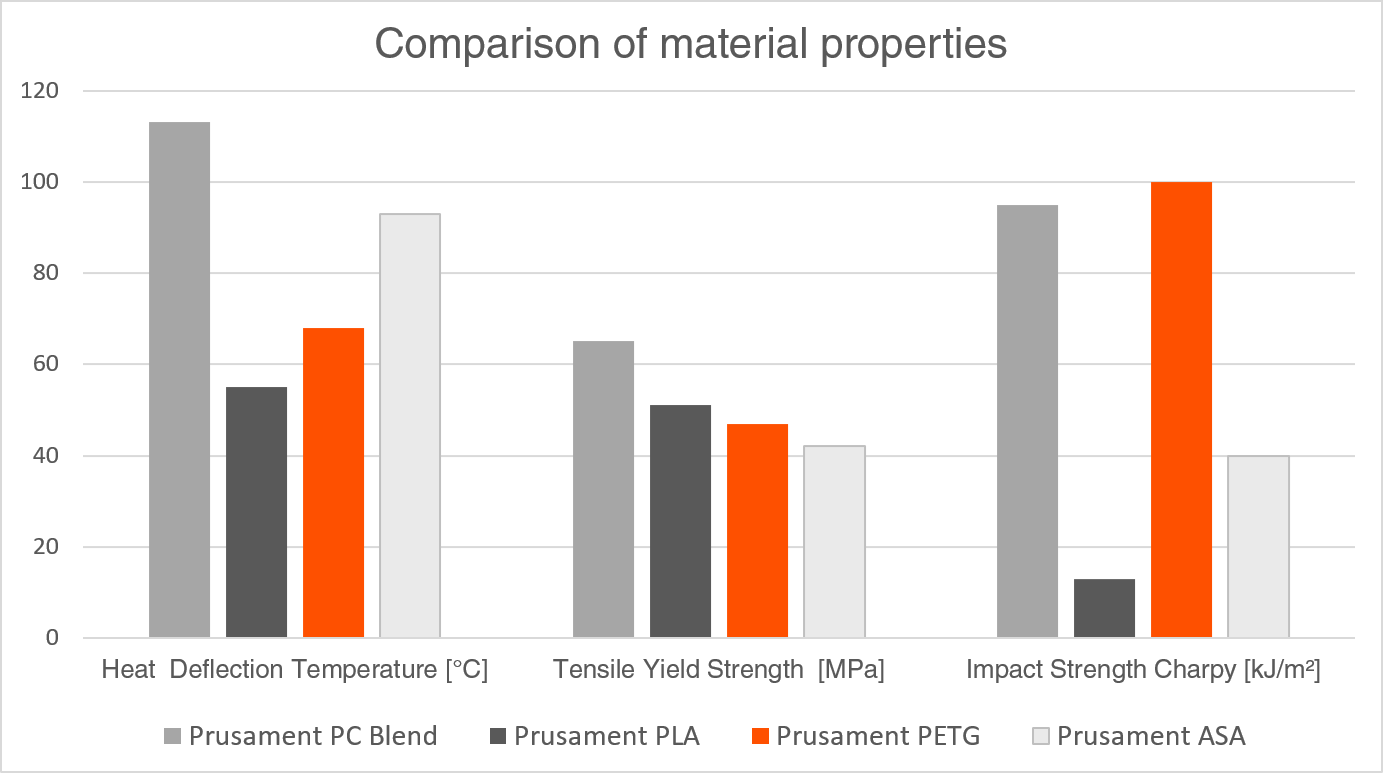

Polycarbonate 3d printing material properties. From our research the material seems to stick the best with slow thick extrusions on the first layer. Compare metrics for strength stiffness density etc. Here we have listed all our 3d printing material along with th key values for their main physical properties. Material properties in stereolithography sla 3d printing.

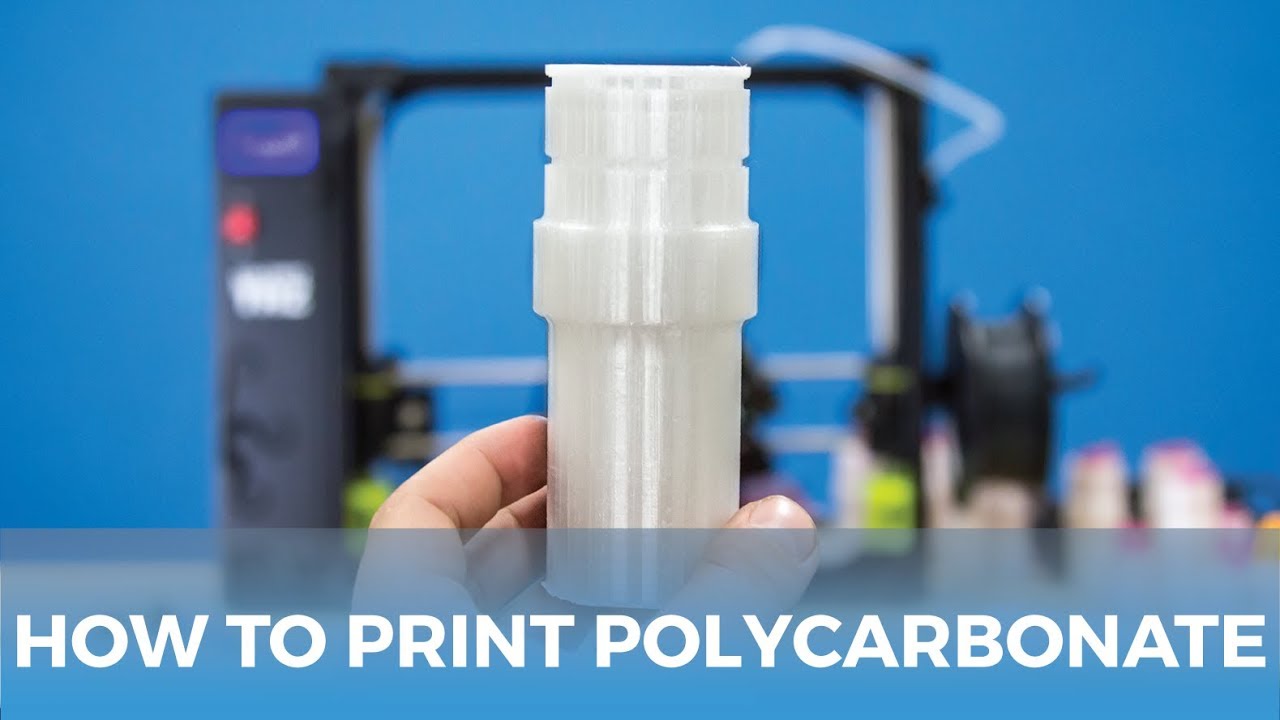

You do need a large heater to reach that 220 degrees c melting point but abs becomes soft and pliable when heated and then sets quickly. Polycarbonate is a famously tough yet challenging material to 3d print due to its unique properties. Asa is a material that has. The strongest 3d printing material.

Polycarbonate filament that isn t sufficiently dry before printing or manufactured poorly will not print properly and can cause defects and issues that will waste your time. We recommend using a first layer height of 100 150 a first layer width of 12 150 and a first layer speed of 15 30. Plastics are made out of long carbon chains whereas resin is a plastic composed of short er carbon chains. When it comes to strength polycarbonate truly is the king of 3d printer filament dramatically out performing other materials in strength tests in an informal material strength test airwolf 3d printed a series of hooks using a variety of 3d printing materials.

News printables buyer s guides reviews basics. Abs pla nylon 910 and polycarbonate. These properties make abs very suitable for 3d printing. Finding quality polycarbonate 3d printing filament.

Quality polycarbonate filament is a necessity if you want a good polycarbonate print. To understand material properties we need to start with the stereolithography process and its raw material the resin. This properties table compiles physical and mechanical properties for the top 3d printing materials. Abs filament is the most commonly used 3d printing plastics.

It is used in the bodywork of cars appliances and mobile phone cases. Ensure success with polycarbonate 3d printing using this helpful guide. Due to the high warping tendency of polycarbonate the first layer is extremely important when printing with this material.