Polycarbonate Injection Moulding Troubleshooting

The 4m approach outlines a specific troubleshooting method for determining the source and correcting it.

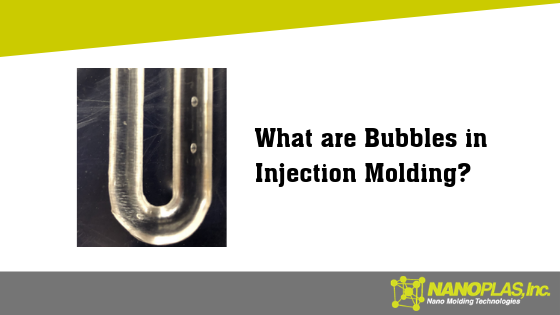

Polycarbonate injection moulding troubleshooting. Injection molding defects include blister air burn marks color streaks delamination flash embedded contaminates etc. Machine used machine setup mould type and complexity materials and manufacturing environment. Ensure stable melt bedding operation. Analyze the causes of these problems generated from raw materials plastic parts or mold design molding processes etc and propose related solutions.

Check the injection and plasticizing capacity of plastic injection molding machine and then compared with the actual quantity of injection molding and plastics consumption per hour. This article introduced nearly all of injection molding defects that you may meet in the process of injection molding. Most defects respond to one of a variety of process and or material changes. We can never dismiss the fact that injection molding is arguably the most versatile technique for producing parts and products.

Injection moulding troubleshooting guide please note the injection moulding troubleshooting guide covers some of the common problems encountered with this process but is by no means complete. As the pet preforms s quality affects a lot in the following step pet preform blowing process. As the term implies short shots can be described as a situation where a molding shot falls short. It happens that this process is somewhat fast works with numerous plastic materials and can provide a durable and highly detailed final product.

The article aims to plastic injection molding problems and solutions mainly as follows. Conditions are variable and include. Injection molding machine s capacity is too small. Short shots are a phenomenon in which the mold cavity cannot be completely filled.

Chapter 42 of injection molding advanced troubleshooting guide. All of injection molding defects may caused by poor mold design incorrect operation of injection molding machine or poor tooling design. Increase the injection speed. Plastic pet preform injection molding troubleshooting.

The defect could be due to any number of issues with the molding process the mold itself the machine or the material. Troubleshooting guide for injection molding troubleshooting is the art and science of remedying defects after the process has demonstrated the ability to produce acceptable production parts. Raise the temperature of the mold or molten plastic. Common problems in polycarbonate injection molding.

Here is the thing. Switch to a less viscous plastic or one with a lower melting temperature. Adjust the design for the flow pattern to be a single source flow.