Plate Rolling Machine Design Calculations Pdf

Design calculations the whole machine elements are designed using books design of machine elements by author v b bhandari and p s gill design data book 2 1 selection of pipe.

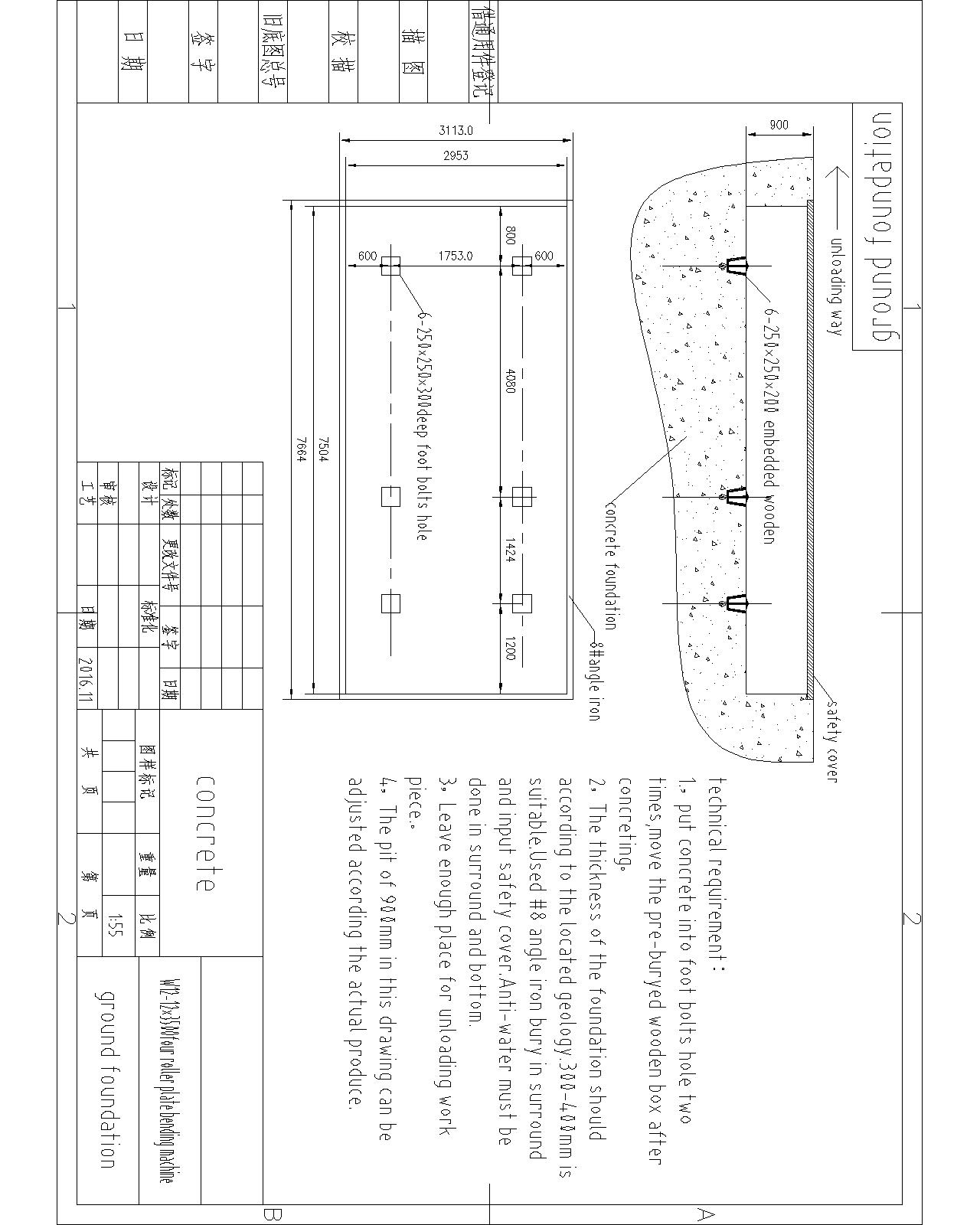

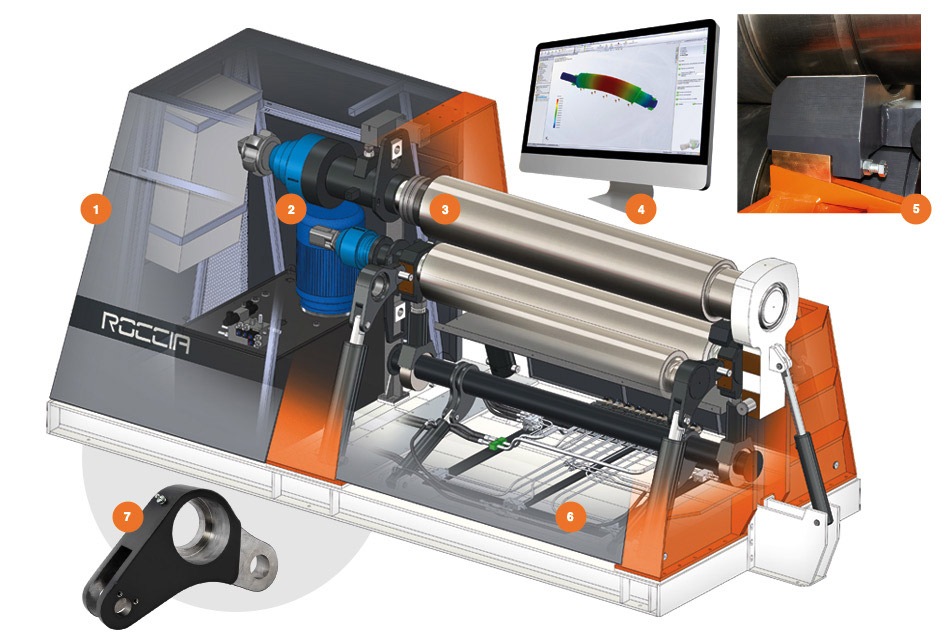

Plate rolling machine design calculations pdf. The sheet metal rolling machine works according to the principle of three point bending. In this post the calculation of the force capabilities of symmetrical three roll bending machine is one of the methods the other types of plate rolling machine can take it for reference. These two methods are combined in one single machine to work smoothly and efficiently. Amazing biggest steel bending machine at work fast extreme large plate rolling machines.

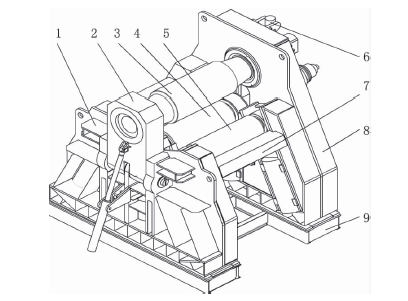

Bending method for rolling operation. Calculations of components 3 1 design of spur gear material en8 hardened and tempered s ut 550n mm 2. Rolling machine for small scale manufacturers ijert vol 1 may2013. Whereby the bent plate can be removed from the machine.

To reduce the time for operation. Of mechanical engineering abhagaikawadpatil engineering college nagpur maharashtra india abstract metal forming can be defined as a process in which the desired size and shapes are obtained through plastic deformation of a material. Nantong weili cnc machine tool co ltd. Amol 2 student1 asst prof2 dept.

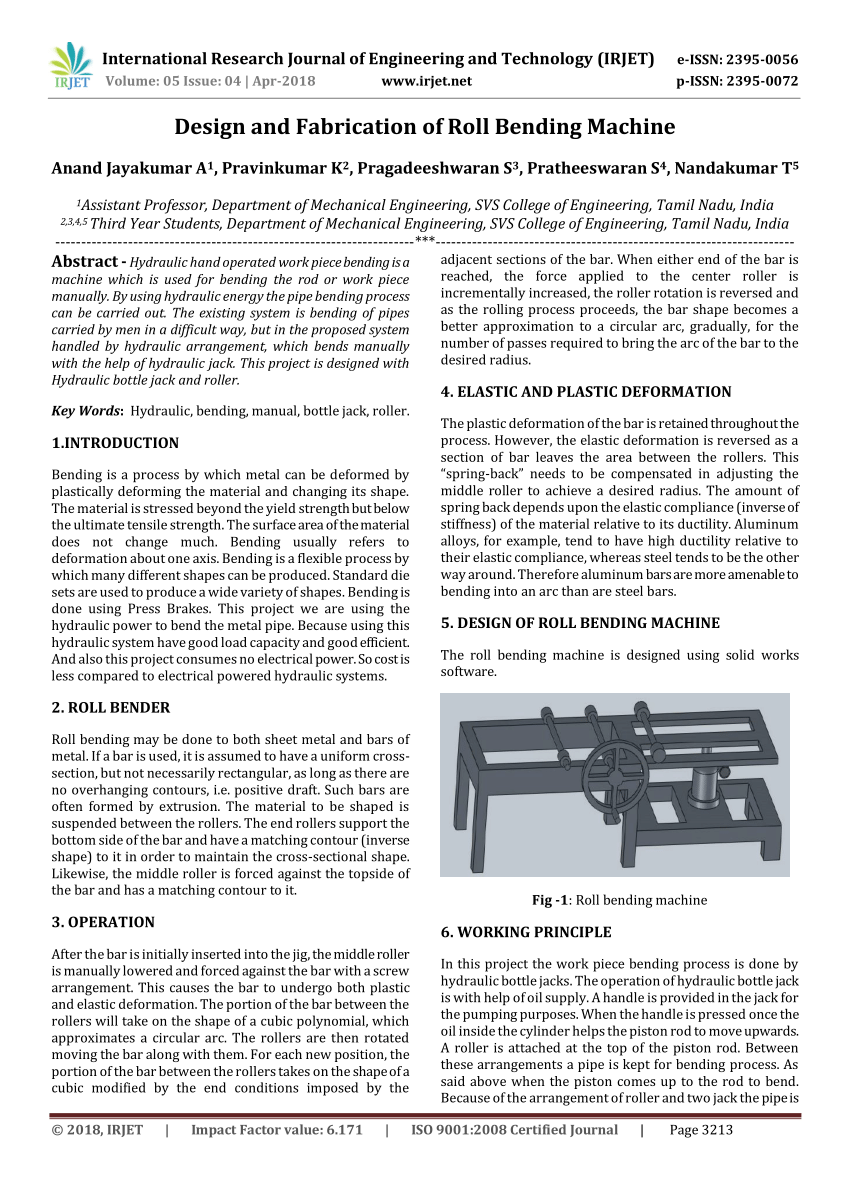

Design and fabrication of sheet rolling machine a project report. In this research paper he developed metal sheet rolling machine for small scale industries the market survey of rs bello show that the price or cost of imported component of. To make on simple working principle. Therefore the calculation of the force analysis and driving power of the plate rolling machine is very important to the design of the roll bending machine.

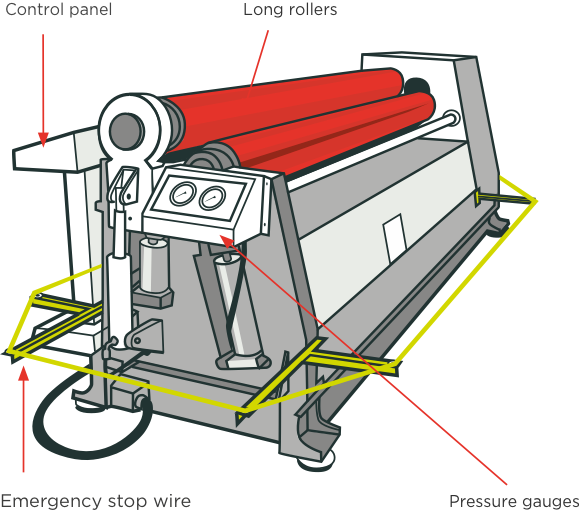

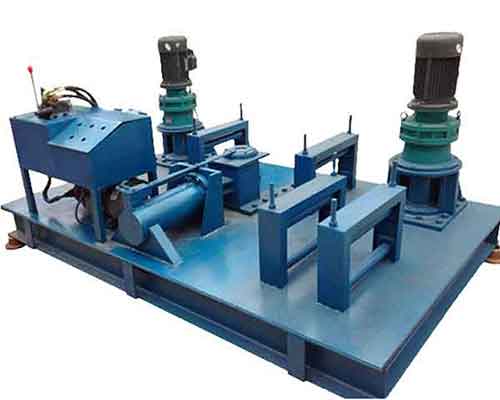

Although there are many. The following are the objectives of the work. To make in minimum cost. The present innovation relates to the plate bending machine which operates with rollers.

The rotation of the driven rolls being utilized to feed the metal through the rolls by means of the frictional forces present between the surface of the rolls and sheet.