Plate Heat Exchanger Calculation Formula

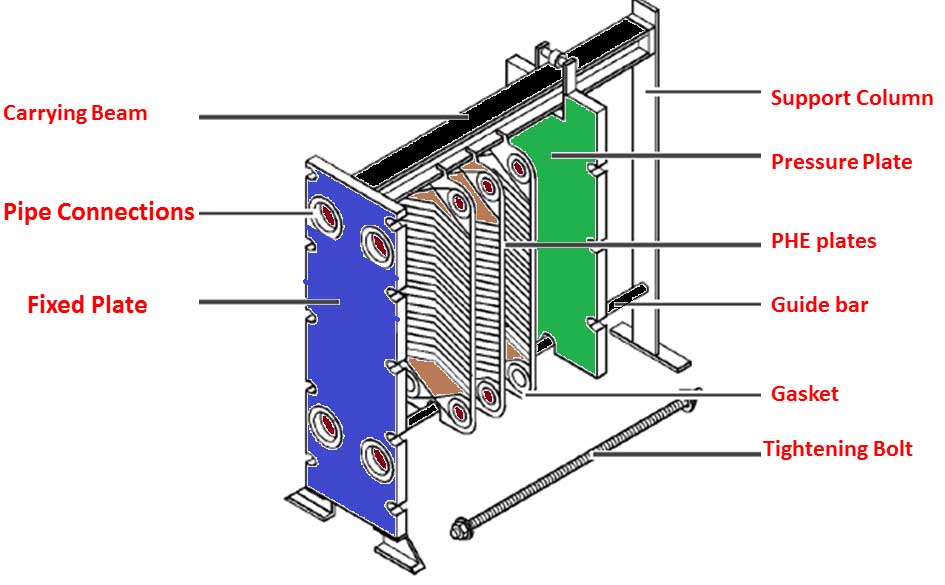

M α 1 the heat transfer coefficient between the warm medium and the heat transfer surface w m2 c α 2 2 the heat transfer coefficient between the heat transfer surface and the cold medium w m c.

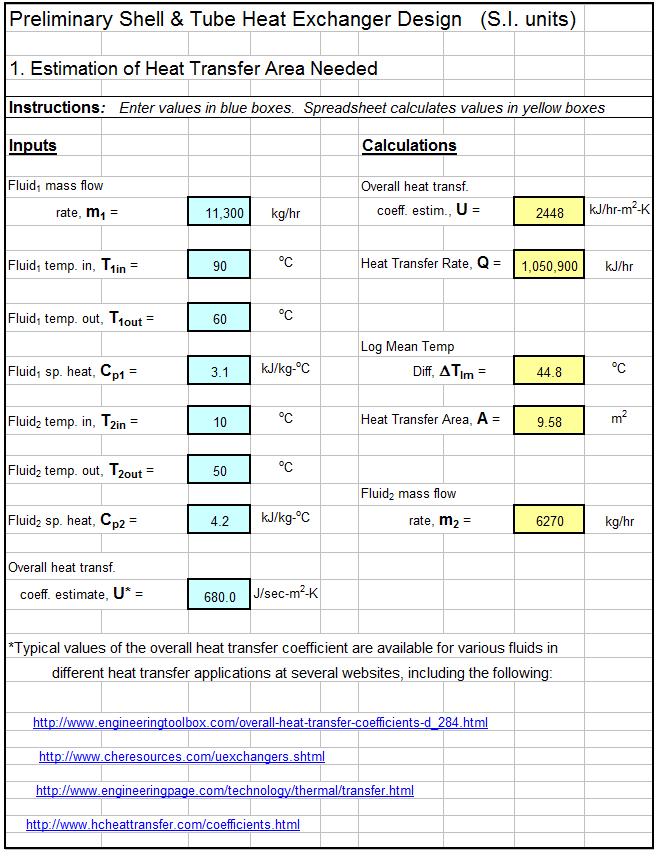

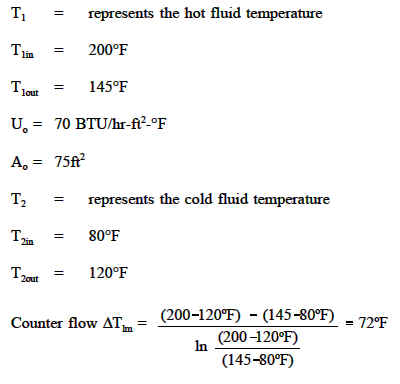

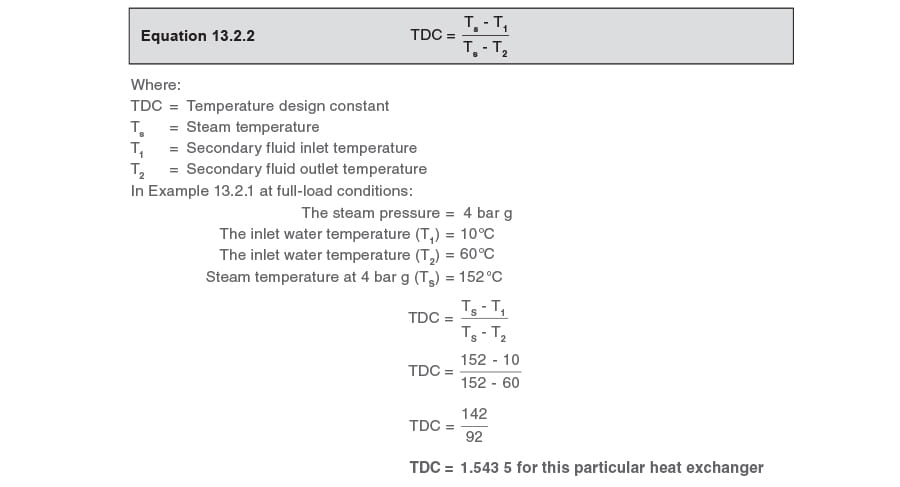

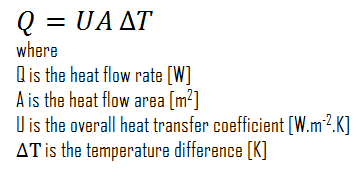

Plate heat exchanger calculation formula. R d 0 0002 m 2 k w fuel oil. The heat exchanger design equation q u a δtlm can be used to determine the required heat transfer area a for a heat exchanger. P heat load btu h m mass flow rate lb h c p specific heat btu lb f δt temperature difference between inlet and outlet on one side f k heat transfer coefficient btu ft 2 h f. The total overall heat transfer coefficient k is defined as.

R d 0 0009 m 2 k w. 1 4 example for plate type heat exchanger heat transfer area calculation. H th ca wm qw 1 s tc tw. U d overall heat transfer coefficient of heat exchanger after fouling w m 2 k u overall heat transfer coefficient of clean heat exchanger w m 2 k 1 can also be expressed as.

The heat transfer performance and the pressure drop in heat exchanger depend on the. R d 0 00009 m 2 k w boiler feed water treated above 325 k. It is then possible to calculate the heat transfer coefficient h on both hot and cold side and then calculate the overall heat transfer coefficient h. The heat load of a heat exchanger can be derived from the following two formulas.

1 2 example for estimate vapour flow rate requirement to achieve required outlet temperature of the cold fluid. Q m h c ph t hin t hout m c c pc t cout t cin where. This video describes how much steam is required to raise temperature of water to a certain degree in a heat exchanger. 1 the design margin m is calculated as.

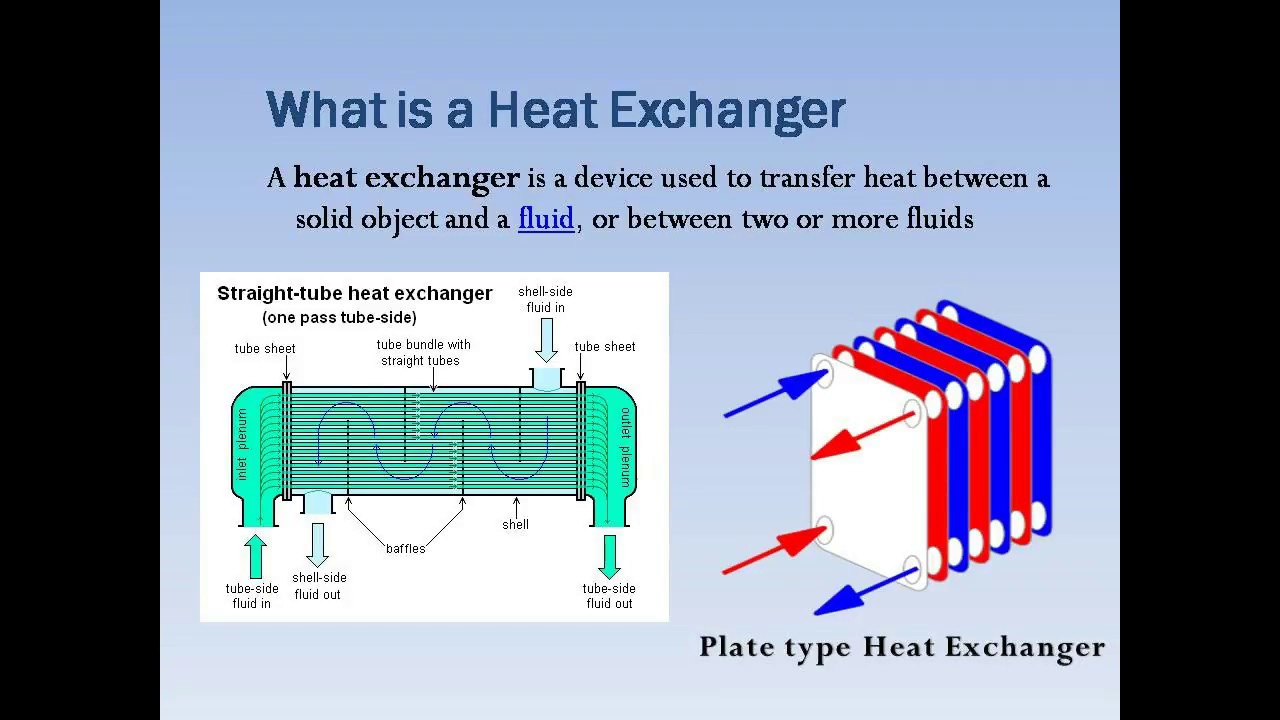

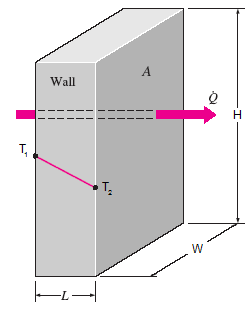

Heat load theta and lmtd calculation. 1 plate heat exchanger heat transfer area calculation phe design calculation. Plate type heat exchangers show that the overall performance in each heat exchanger are elucidated. The enthalpy transfer efficiency for an heat recovery unit can be calculated as.

1 1 example for finding cold fluid outlet temperature. The thermal efficiencies at the maximum power outputs will be calculated as the formula. Following is the equation to be used. Heat exchanger calculations with the heat exchanger design equation require a value for the heat transfer rate q which can be calculated from the known flow rate of one of the fluids its heat capacity and the required temperature change.

X 1 moisture outside make up air before the heat exchanger kg kg grains lb x 2 moisture outside make up air after the heat exchanger kg kg grains lb x 3 moisture outlet air before the heat exchanger kg kg grains lb enthalpy transfer efficiency.