Pcb Conformal Coating Cost

Highly effective for removal of acrylic urethane and silicone printed circuit board coatings.

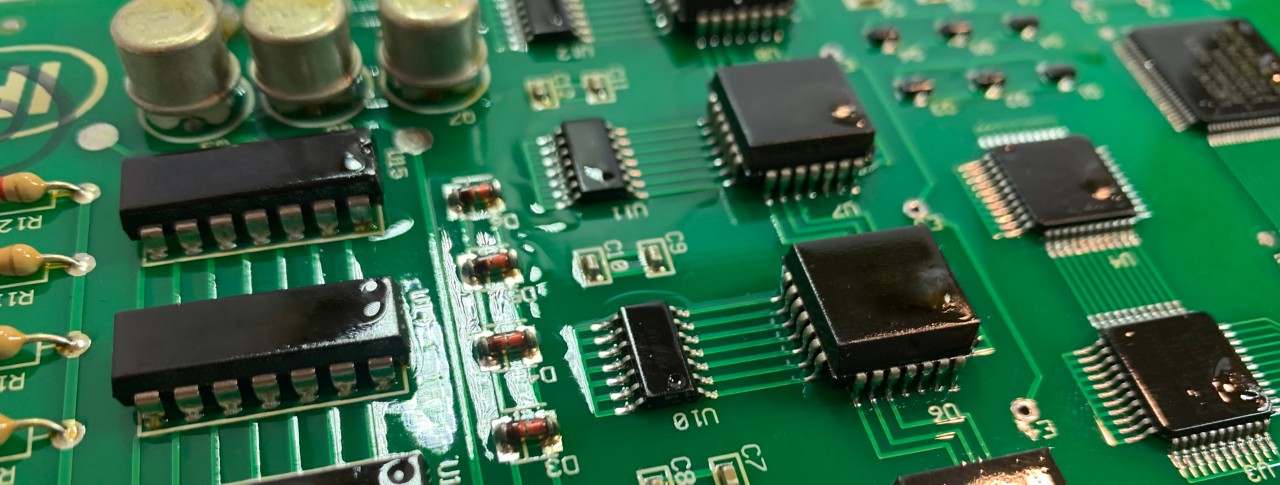

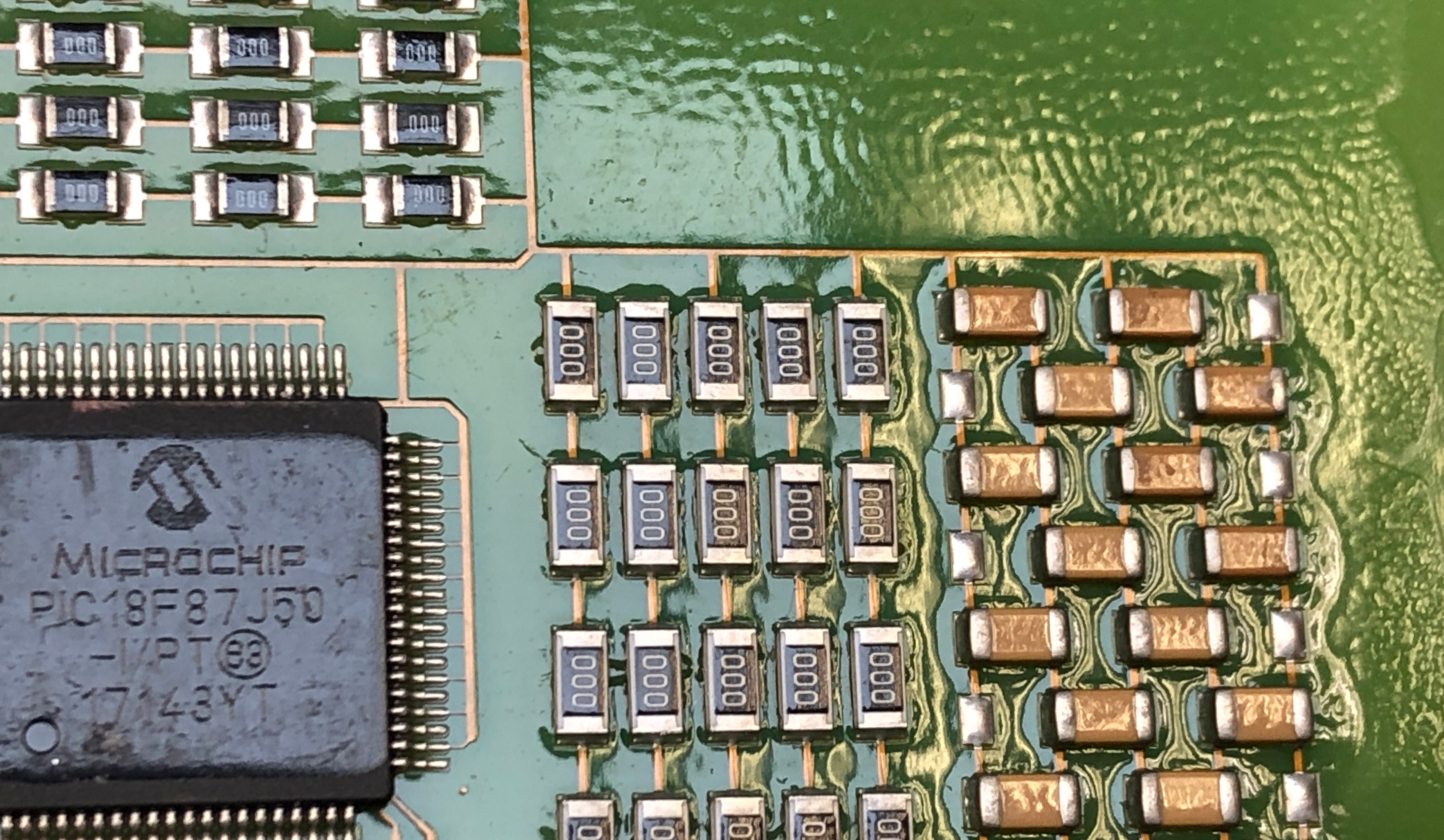

Pcb conformal coating cost. Pcb conformal coating is the process of applying a polymer film of 25 75µm thick 50µm typical to safeguard the components in the printed circuit boards. 3 questions to help you estimate cost. A pcb conformal coating is a protective chemical coating or polymer film 25 75µm thick 50µm typical that conforms to the circuit board topology. Aircare is one of the prominent manufacturer supplier solution provider of a comprehensive range of industrial equipment.

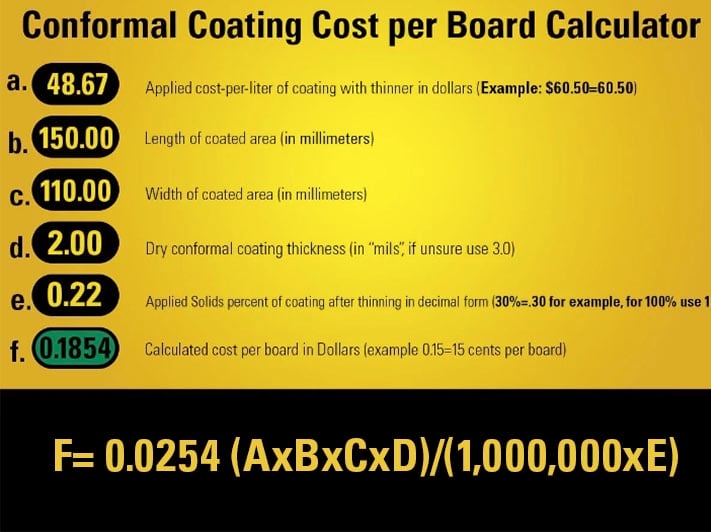

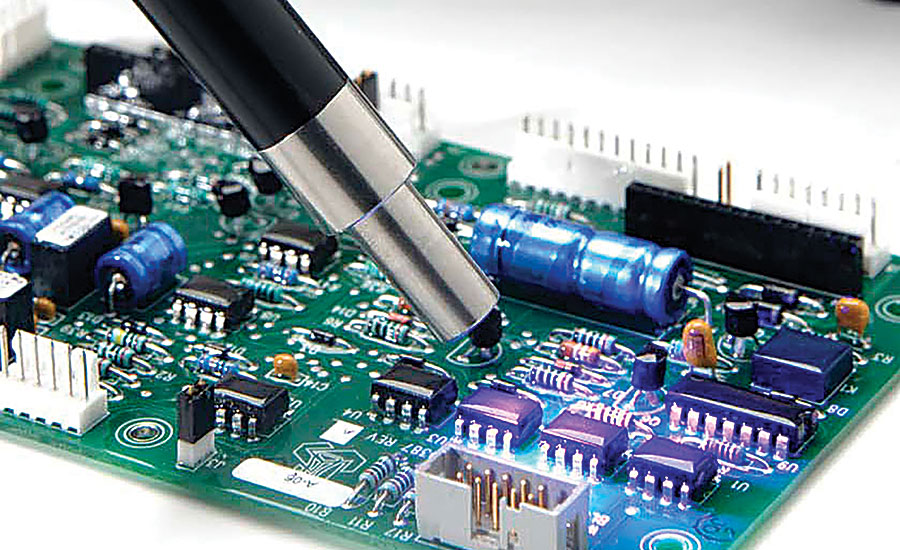

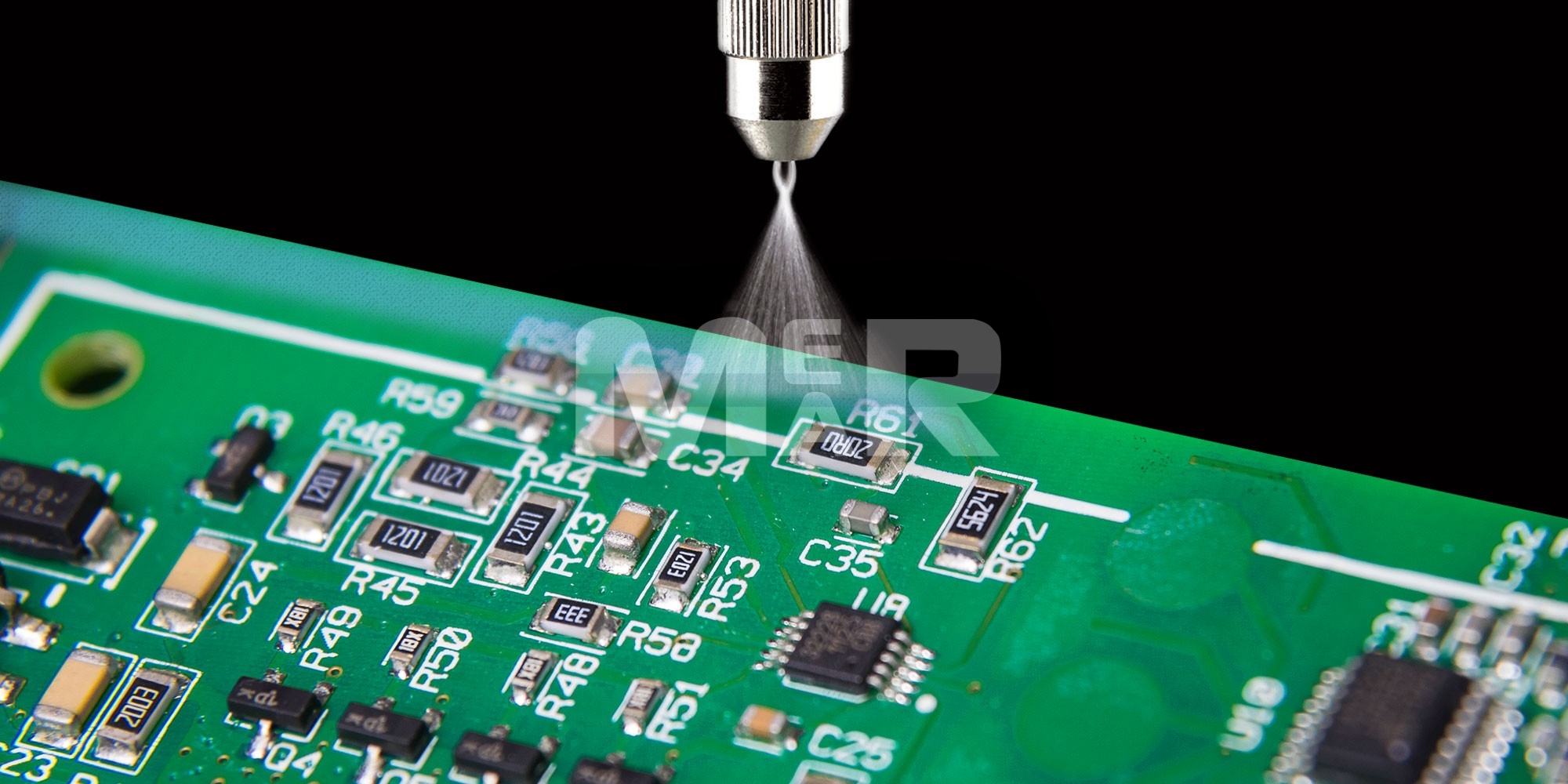

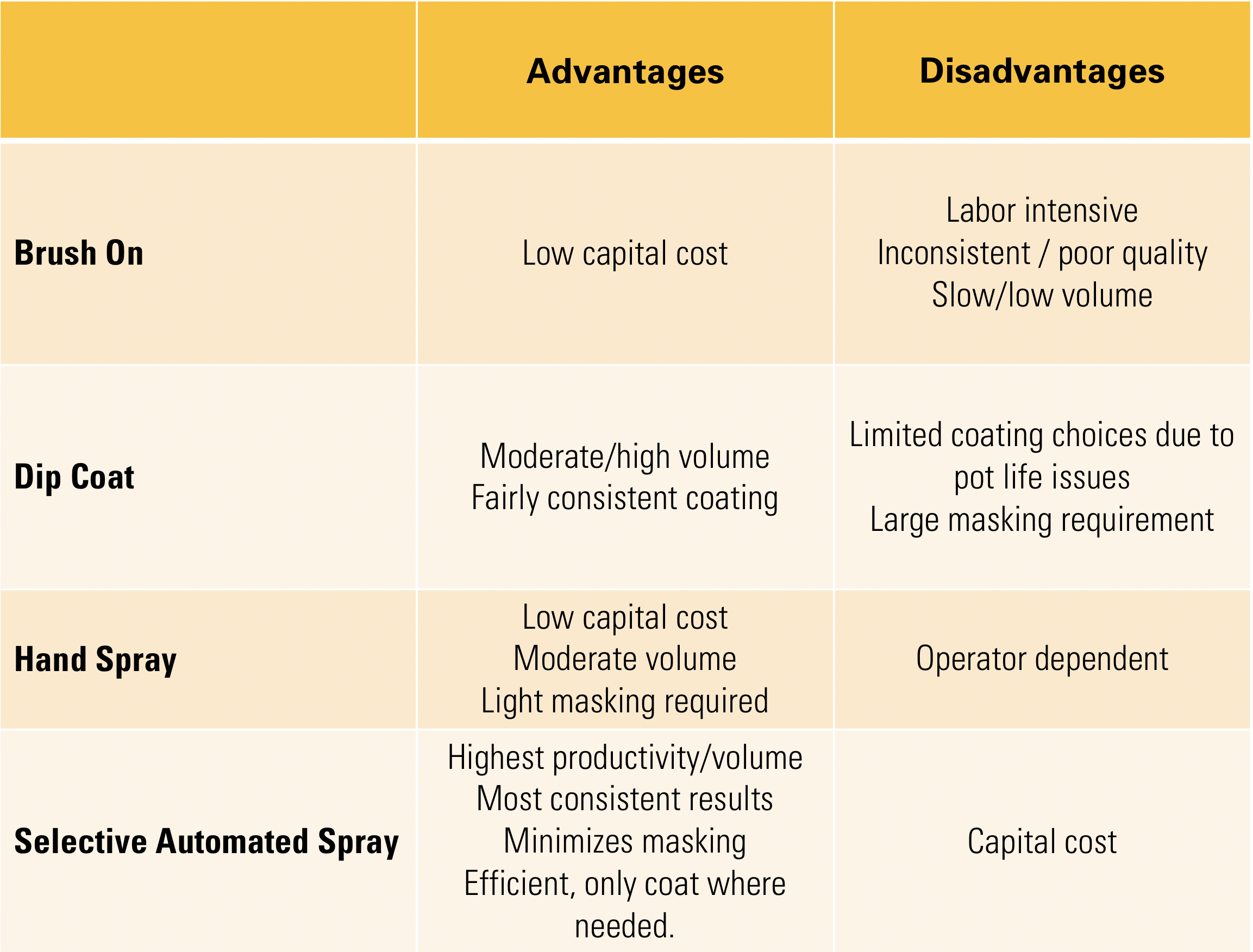

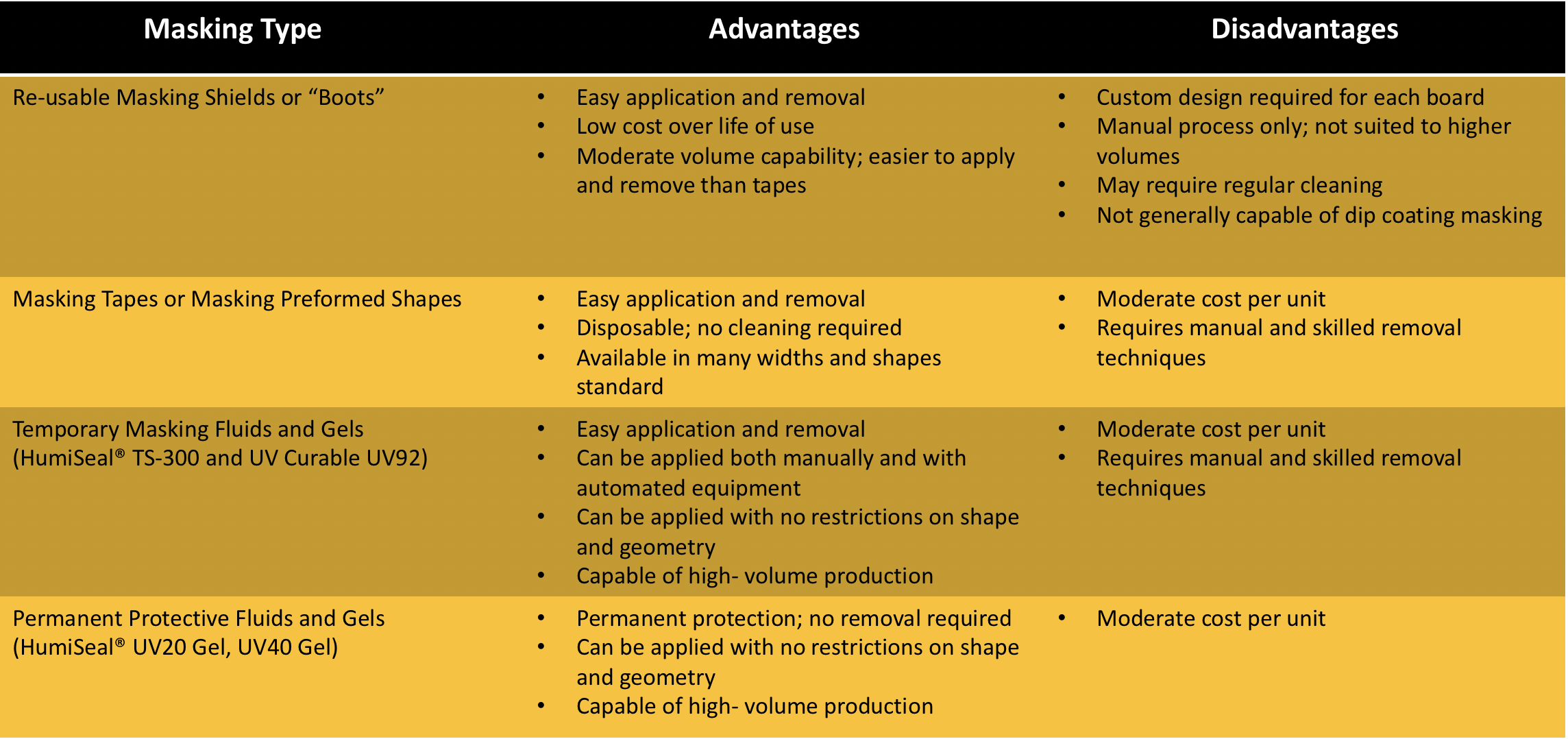

Conformal coating material is a thin polymeric film which conforms to the contours of a printed circuit board to protect the board s components. Coatings can be applied in a number of ways including brushing spraying. Its purpose is to protect electronic circuits from harsh environments that may contain moisture and or chemical contaminants. Conformal coatings 18 conformal coating application 10 conformal coating process 7 conformal coating benefits 6 uv curable type ar ur 6 events 5 uncategorized 5 humiseal 4 adhesive solutions 3 conformal coating costs 3 humiseal blog 3 protection for pcb 3 vibration suppression 3 electronic protection 2 encapsulants 2.

Established in 1998 our range includes direct and indirect evaporative air cooling air ventilation air distribution product air circulation product and cost effective fouling prevention and water treatment equipment. Parylene raw material costs most parylene runs require about a pound of raw parylene dimer. As modern household appliance industry pays more and more attention to the product function reliability conformal coating the concept is being mentioned by manufacturers more and more. Chemical solvent method for conformal coating removal.

A detailed process and guide for removal can be found in section 2 3 2 of the circuit technology center s ctc guide for coating removal. From the design phase onward suppliers and contract manufacturers are being asked by their oem overlords for increased. A single pound of dimer can cost anywhere from 200 to 5 000 per pound with cost differences dictated by the type and quality of the parylene. Typically applied at 25 250 μm micrometers thickness it is applied to electronic circuitry to protect against moisture dust chemicals and temperature extremes.

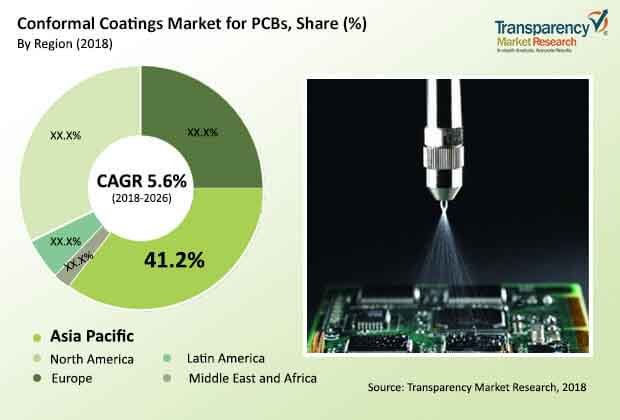

The pcb industry continues to evolve with ever increasing demands for efficiency and manufacturing cost reductions. The potential cost of not conformal coating your pcb. Posted by dan griffin on jan 23 2020 10 00 00 am tweet. There are many different facets to conformal coating from equipment and applications to the different types of coatings.